Last Christmas, I got a LED-based lamp that you can clip onto a book for

reading in dark places, e.g., in bed without lighting the whole room. It's

very handy, lightweight and it lights both pages of a book very well. It would

be perfect if it didn't require Lithium batteries (CR2032, button-shaped

batteries, 20 mm diameter and 3.2 mm thick). These batteries are expensive if

bought in small amounts, and they need to be replaced often compared to e.g.,

AAA batteries (at least in theory).

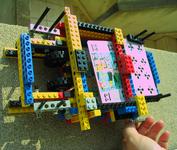

So I decided to fit AAA batteries onto it. The original lamp's design is very

simple: two 3V batteries in series, one white LED, a switch and that's it. No

fancy electroncics, no black magick: you can't make it any simpler. So

replacing the Lithium batteries with alkalines is very simple in theory: fit a

holder for 3 AAA alkaline batteries, add a 33 ohms resitor in series, connect

the wires to the contacts, and Bob's your uncle. In practice, it was a bit

more difficult, but not much.

3-AAA Battery Holder

The electronics shop I went to didn't have any 3-AAA holders, only 1 piece or 4 pieces

holders. So I went for three times one and I glued them together with

cyanoacrylate glue, after sanding the surfaces to ensure that they

were perfectly flat.

Then, I needed to connect the three batteries in series. This has been done

with the legs of the resistor.

I added two wires from the remaining connectors and routed them through the

ready-made holes in the holders. To one of the wires, I soldered the

resistor. It rests in the angle of the battery holder: since the holder is

square, and the battery is round, there is some space left along the sides,

enough for a wire or even a resistor. I used insulation tape to prevent contact

between the soldered resistor and the battery.

Lid Replacement

The original lid for the battery compartment is nicely round and everything,

but this makes it impractical to glue anything onto. I therefore decided to

make my own replacement for this part, which would be flat (and probably

ugly). I got a piece of Plexiglas (PMMA, or acrylic glass) from a friend, and

cut a piece of more or less the right shape. The fitting was actually quite

difficult, because the battery compartment has several screws and bits that

are protruding slightly. It required a lot of sanding before getting a good

enough fit. Plexiglas can be bent slightly, but if the back of the support

wouldn't be flat, the battery holder could not be glued anymore with

cyanoacrylate (which requires perfectly matching surfaces for bonding). Thank

$DEITY for powertools!

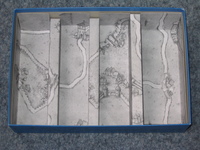

This is the inside of the battery compartment. It has one screw on the left,

two protruding rings holding the original CR2032 batteries, and two more

screws on the right. Moreover, it has a slot in the far left where the lid's

tail bit goes. The next picture shows this tail bit, on the far left of the

support piece.

The tail bit is made of a piece of the same plexiglas sheet as the support. I

glued it in the right place with cyanoacrylate, and then I sanded it until it

was thin, short and narrow enough to fit into the slot. The two next pictures

show more of the sanding that was needed in order for the lid to fit on top of

the screws and other bits. The first picture shows the tail bit again on the

left, as well as a hole for the screw located next to the slot. The second

picture shows the hole through which the fixation screw goes, as well as the

places where the two other screws go. On both pictures, you can see the

central hole where the wires go through to the contacts in the lamp's original

battery compartment.

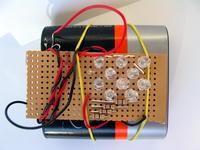

The next two pictures show the whole device I built, including the contacts,

from two more angles. You can see the resistor wrapped in red insulation tape.

Contacts

My first idea was to use two 10 eurocents coins as contacts, since they have

almost exactly the same diameter (19.75 mm) as the original batteries (20 mm)

while being a bit thinner, which would have allowed to add the wires or some

kind of foam adding pressure and maintaining the electrical contact. It was a

bad idea: soldering onto the coins is difficult, because the coin acts like a

heat sink for the soldering iron and the tin, instead of reaching the right

temperature that would allow to make a proper solder. Well, it's not that bad:

the device is 0.20 EUR cheaper this way.

Instead, I used aluminium folio, cardboard and double-sided tape to build

round contacts that fit into the battery holes, as shown on the three next

pictures.

Integration

Finally, here's the device with its batteries, mounted onto the lamp:

It looks quite “hacker-techno-raw” (or whatever you want to call it), but it

works. It's of course heavier than the original lamp, but the clamp is strong

enough to hold even on a paperback. The only drawback is that the angles are

still quite sharp, and the battery pack hurts the skin when it lies on your

lap.

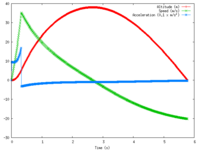

Electricity Consumption

The 3 AAA batteries give 4.6 V without a load (i.e., when the lamp is off) and

4.5 when it's on. The voltage across the 33 R resistor is 0.7 V, which gives a

21 mA current and 3.8 V across the LED, which look like the nominal values one

can find on the Web. The LED therefore consumes 80 mW and 15 mW are wasted in

the resistor and the batteries' internal resistance (that's about 16%).